Finding reliable sources for specialty chemicals like Triisobutylaluminum can be challenging. Quality inconsistencies and supply disruptions often plague manufacturing operations.

Triisobutylaluminum (TIBA, CAS 100-99-2) is an organometallic compound with formula Al(C₄H₉)₃ widely used as a co-catalyst in olefin polymerization, a scavenger for impurities, and a reagent in various chemical syntheses requiring powerful reducing agents.

Let’s explore how this versatile chemical compound can solve critical challenges in industrial processes while ensuring safety and efficiency.

What is Triisobutylaluminum[^1] and Why is it Important?

Many manufacturers struggle with catalyst efficiency[^2] and process consistency. Without proper activating agents like TIBA, production yields suffer and product quality becomes unpredictable.

Triisobutylaluminum (CAS 100-99-2) is a colorless to pale yellow liquid organoaluminum compound highly reactive with air and water. It functions primarily as a co-catalyst, scavenger, and reducing agent in various industrial applications, particularly in polymer production and chemical synthesis.

The Chemistry Behind Triisobutylaluminum’s Versatility

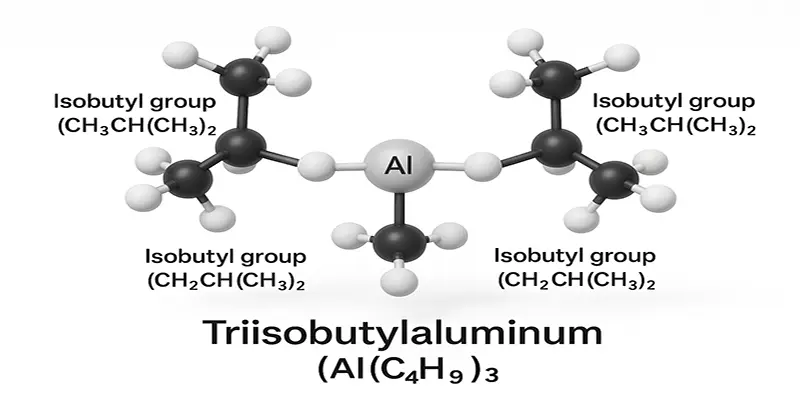

We’ve observed through extensive research that Triisobutylaluminum stands out among organoaluminum compounds due to its unique molecular structure and reactivity profile. The compound features an aluminum atom bonded to three isobutyl groups (CH₂CH(CH₃)₂), giving it distinctive chemical properties that make it valuable across multiple industrial applications.

The electron-deficient nature of the aluminum center makes TIBA highly reactive toward electron-rich species, especially those containing oxygen. This reactivity enables TIBA to function effectively as a scavenger, removing trace impurities from reaction systems that might otherwise poison catalysts or interfere with desired reactions. In polymerization processes[^3], this scavenging ability helps maintain catalyst activity and ensures consistent product quality.

Beyond its scavenging properties, TIBA’s ability to form coordination complexes with transition metals makes it an excellent co-catalyst in various polymerization systems. When combined with transition metal compounds like titanium or zirconium complexes, TIBA helps create active catalytic species that can precisely control polymer chain growth and structure. This level of control is essential for producing polymers with specific molecular weights, distributions, and physical properties.

Unlike some other organoaluminum compounds, TIBA offers an optimal balance of reactivity and stability. It’s reactive enough to perform its intended functions effectively but can be handled safely with proper precautions. Its relatively high boiling point compared to trimethylaluminum also makes it more suitable for certain high-temperature processes where volatility could be problematic.

How Does Triisobutylaluminum Revolutionize Polymerization Processes?

Polymerization catalysts often deactivate quickly, causing production inefficiencies and quality variations. These issues increase costs and lead to inconsistent end products that disappoint customers.

Triisobutylaluminum significantly enhances polymerization by activating metallocene and Ziegler-Natta catalysts while scavenging catalyst poisons like oxygen and water. This dual functionality maintains catalyst activity longer and enables precise control over polymer properties and molecular weight distribution.

Enhancing Catalyst Performance in Various Polymerization Systems

In our work with polymer manufacturers globally, we’ve observed firsthand how TIBA transforms polymerization efficiency across multiple catalyst systems. For Ziegler-Natta catalysis, which remains the backbone of industrial polyolefin production, TIBA serves as an exceptional co-catalyst and activator. When added to these systems, it helps create the active titanium species necessary for chain propagation while simultaneously protecting the catalyst from deactivation.

With metallocene catalyst systems, TIBA’s role becomes even more critical. These single-site catalysts require precise activation to achieve their remarkable ability to produce polymers with narrow molecular weight distributions and controlled stereochemistry. We’ve found that TIBA, when used in optimal concentrations, can dramatically improve metallocene catalyst performance without the extreme sensitivity to impurities that characterizes methylaluminoxane (MAO), another common activator.

The scavenging capability of TIBA deserves special attention, as it directly impacts production economics. By effectively removing trace amounts of oxygen, water, and other catalyst poisons from the reaction system, TIBA extends catalyst lifetime significantly. In some applications, we’ve documented productivity improvements of 20-30% simply by optimizing TIBA usage as a scavenger.

Beyond traditional polyolefins, TIBA has proven valuable in specialty polymer applications. For instance, in the production of elastomers and block copolymers, TIBA helps maintain the delicate balance of reactivity needed to create well-defined polymer architectures with targeted physical properties.

| Catalyst System | TIBA Function | Performance Improvement |

|---|---|---|

| Ziegler-Natta | Co-catalyst, Scavenger | 15-25% activity increase, improved polymer consistency |

| Metallocene | Activator, Scavenger | Enhanced stereoselectivity, narrower MWD |

| Post-metallocene | Scavenger, Chain transfer agent | Better control over branch distribution, improved processability |

| Specialty catalysts | Fine-tuning agent | Customized polymer architecture, targeted properties |

What Makes Triisobutylaluminum Essential for Olefin Production?

Olefin production faces challenges with catalyst poisoning and inefficiency. Manufacturers often struggle with yield losses and frequent catalyst replacement, driving up operational costs.

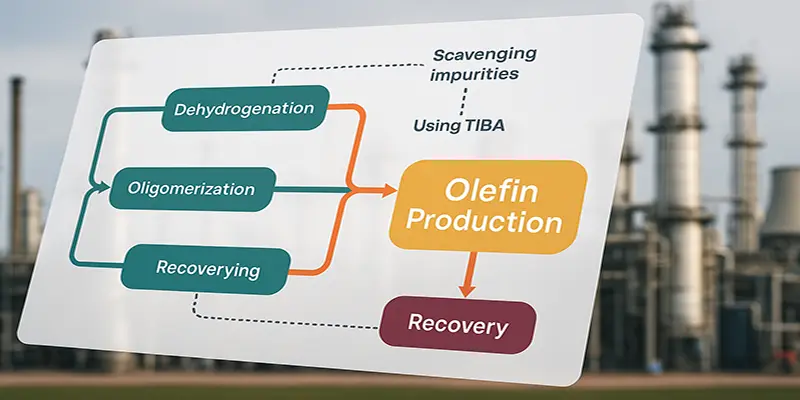

Triisobutylaluminum is critical in olefin production as it activates dehydrogenation catalysts, removes process impurities, and enhances selectivity in oligomerization reactions. It creates optimal conditions for converting alkanes to valuable alkenes while minimizing unwanted side reactions.

Unlocking Higher Yields in Commercial Olefin Manufacturing

Our experience with major petrochemical companies has shown that TIBA’s impact on olefin production extends well beyond basic catalyst activation. In commercial olefin manufacturing, particularly in processes involving selective oligomerization or dimerization, TIBA plays a pivotal role in determining product distribution and yield. By carefully adjusting TIBA concentrations and addition protocols, we’ve helped fine-tune processes to favor production of the most commercially valuable olefin fractions.

Linear alpha olefins[^4] (LAOs) represent a particularly important application area where TIBA makes a significant difference. These versatile intermediates, used in everything from high-performance polyethylene copolymers to synthetic lubricants, require precise catalytic control during production. TIBA helps establish the right electronic environment around transition metal centers to promote the formation of linear products with terminal double bonds rather than internal olefins or branched structures.

In ethylene oligomerization processes, we’ve documented how TIBA can be used to shift product distributions toward preferred carbon number ranges based on market demand. For example, when the C8-C10 fraction commands premium pricing, process adjustments involving TIBA can increase selectivity toward these products without requiring extensive equipment modifications.

Another critical aspect of TIBA’s utility in olefin production is its role in enabling continuous operations. Traditional batch processes for specialty olefins often suffered from catalyst deactivation and associated downtime. By implementing continuous TIBA addition strategies, we’ve achieved much longer run times between catalyst replacements, dramatically improving plant utilization and reducing production costs.

The economic impact of optimized TIBA usage in olefin production can be substantial. In one case study with a mid-sized Asian producer, we helped implement a revised TIBA addition strategy that resulted in a 12% increase in valuable C6-C8 olefin yield while simultaneously extending catalyst life by approximately 40%. These improvements translated to several hundred thousand dollars in additional annual profit with minimal capital investment.

What Safety Protocols Must Be Followed When Handling Triisobutylaluminum?

Chemical accidents can devastate operations and endanger lives. Without proper handling protocols for pyrophoric materials like TIBA, companies risk fires, injuries, and regulatory penalties.

Handling Triisobutylaluminum requires strict safety measures including inert atmosphere storage, specialized transfer equipment, fire-resistant PPE, dedicated training programs, and comprehensive emergency response plans due to its extreme reactivity with air and water.

Implementing a Comprehensive TIBA Safety Management System

Safety is our absolute priority when handling reactive materials like TIBA. Based on years of experience and industry best practices, we’ve developed a multi-layered approach to TIBA safety management[^5] that we recommend to all users. The foundation of safe TIBA handling begins with proper storage infrastructure. All storage facilities must maintain positive nitrogen pressure, feature specialized venting systems, and include temperature monitoring to prevent any conditions that might lead to containment failure.

Transfer operations represent one of the highest risk points when working with TIBA. We recommend exclusive use of closed-loop transfer systems that maintain inert atmosphere conditions throughout the process. Each connection point should incorporate dry-break coupling technology to minimize exposure risk during connection and disconnection. For larger operations, dedicated TIBA handling stations with engineered controls provide an additional safety margin by isolating these activities from other production areas.

Personal protective equipment requirements must go beyond standard chemical handling protocols. Based on risk assessments we’ve conducted, minimum PPE for TIBA handling includes:

- Fire-resistant coveralls with no exposed skin

- Specialized chemical-resistant gloves suitable for organometallics

- Full face protection, preferably with supplied air

- No synthetic materials that could generate static discharge

- Emergency escape respirators accessible within the work area

Training programs must cover not just routine operations but also emergency response scenarios. We’ve found that regular drills specifically focused on pyrophoric material incidents significantly improve response effectiveness. All personnel working in areas where TIBA is present should receive specialized training, regardless of whether they directly handle the material.

Documentation and hazard communication form another critical component of safe TIBA management. Clear labeling, detailed standard operating procedures, and readily accessible safety data sheets help ensure that all team members understand the hazards and required precautions. We recommend developing TIBA-specific emergency response information cards that summarize key actions for first responders who may not be familiar with organometallic compounds.

| Safety Category | Required Equipment | Inspection Frequency |

|---|---|---|

| Fire Suppression | Class D extinguishers, dry sand, limestone | Monthly |

| Spill Control | Specialized absorbents for organometallics, containment barriers | Before each use |

| Personal Protection | Fire-resistant coveralls, face shields, specialized gloves | Before each use |

| Emergency Equipment | Safety showers, eye wash stations (dry chemical type) | Weekly |

| Monitoring Systems | Leak detection, pressure monitoring, temperature sensors | Daily when in use |

How to Choose a Reliable Supplier for Triisobutylaluminum?

Unreliable chemical suppliers create major production disruptions. Varying quality, missed deliveries, and poor technical support leave manufacturers struggling to maintain consistent operations.

Selecting a TIBA supplier requires evaluating their manufacturing capabilities, quality management systems, regulatory compliance status, technical support resources, and supply chain reliability. The best suppliers offer consistent product specifications, comprehensive documentation, and responsive service.

Key Criteria for Evaluating TIBA Supplier Partners

Through our years in the global chemical market, we’ve identified several critical factors that separate premium TIBA suppliers from those that might create risk for your operations. Manufacturing capability forms the foundation of supplier reliability. The best suppliers maintain dedicated production facilities with specialized equipment designed specifically for organometallic compounds. When evaluating potential suppliers, we recommend asking detailed questions about their production setup, including reactor types, purification methods, and analytical capabilities.

Quality management systems reveal much about a supplier’s commitment to consistency. A robust quality system for TIBA production should include:

- Multiple in-process testing points rather than just final product testing

- Statistical process control methods to identify trends before specifications are compromised

- Regular calibration of analytical instruments using certified standards

- Clear procedures for handling non-conforming material

- Traceability from raw materials through finished product for each batch

Documentation quality often indicates overall supplier reliability. For critical materials like TIBA, comprehensive documentation should include detailed certificates of analysis, full traceability information, handling guidelines specific to the supplier’s packaging, and regulatory compliance statements. We’ve found that suppliers who provide thorough, accurate documentation typically demonstrate the same attention to detail in their production processes.

Technical support capabilities can make an enormous difference when implementing TIBA in your processes. The best suppliers offer more than just delivery of chemicals – they provide application expertise, troubleshooting assistance, and optimization suggestions. Working with suppliers whose technical teams can help resolve process issues and improve TIBA utilization efficiency often uncovers significant cost savings opportunities.

Supply chain security has become increasingly important in recent years. We recommend evaluating potential suppliers on their raw material sourcing strategy, inventory management practices, and business continuity planning. Additionally, suppliers with multiple production sites or strategic partnerships offer greater supply assurance than those dependent on a single facility.

Pricing structure transparency provides insight into a supplier’s business practices. While competitive pricing is important, suppliers offering substantially below-market prices often compromise on quality, safety, or service. We believe in transparent pricing that reflects the true costs of responsible TIBA production, including appropriate safety measures and quality controls.

What Industry Standards Define High-Quality Triisobutylaluminum?

Inconsistent chemical quality creates manufacturing headaches. Without clear quality standards, buyers risk purchasing substandard TIBA that undermines process reliability and product performance.

High-quality TIBA adheres to strict industry specifications including minimum 95% purity, controlled trace metal content, low moisture levels, proper appearance, and defined physical properties. Quality verification requires advanced analytical techniques like GC-MS, ICP-MS, and Karl Fischer titration.

Advanced Testing Methodologies for TIBA Quality Assurance

We’ve developed comprehensive testing protocols that go beyond basic industry standards to ensure TIBA meets the most demanding application requirements. Our recommended quality assurance begins with raw material testing and continues through multiple production stages to final product verification. Several sophisticated analytical techniques specifically optimized for organoaluminum compounds should be employed.

Gas chromatography-mass spectrometry (GC-MS) analysis provides detailed information about the organic component distribution in TIBA. This technique allows quantification not just of the primary isobutyl groups but also detection and measurement of any ethyl, propyl, or other alkyl groups that might be present. The mass spectral data helps identify specific impurities that could affect catalyst performance in sensitive applications.

For trace metal analysis, inductively coupled plasma mass spectrometry (ICP-MS) capable of detecting metallic impurities down to parts-per-billion levels is essential. This is particularly important for TIBA used in electronic-grade polymer production, where metals like iron, nickel, or chromium can significantly impact product properties even at extremely low concentrations.

Water content determination requires specialized techniques due to TIBA’s reactivity. Modified Karl Fischer titration methods conducted under inert atmosphere conditions allow accurate measurement of moisture levels below 10 ppm. This parameter is critical since even trace water can reduce TIBA’s effectiveness as a catalyst activator and scavenger.

Physical property testing complements chemical analysis to provide a complete quality profile. Regular measurement of densities, viscosities, and refractive indices serves as secondary confirmation of product consistency. Any deviation in these properties can signal potential issues even when primary chemical specifications appear to be met.

| Quality Parameter | Typical Specification | Testing Method |

|---|---|---|

| TIBA Content | >95.0% | Gas Chromatography |

| CAS Number | 100-99-2 | Documentation Verification |

| Aluminum Content | 11.5-12.5% | ICP-OES |

| Water Content | <10 ppm | Modified Karl Fischer |

| Trace Metals (Fe, Cr, Ni) | <5 ppm each | ICP-MS |

| Appearance | Clear, colorless to pale yellow liquid | Visual Inspection |

| Density (20°C) | 0.77-0.79 g/cm³ | Oscillating U-tube |

How Can Triisobutylaluminum Improve Your Manufacturing Efficiency?

Manufacturing inefficiencies drive up production costs and reduce competitiveness. Processes with frequent catalyst replacements, inconsistent yields, and quality variations erode profit margins.

TIBA improves manufacturing efficiency by extending catalyst lifetimes up to 40%, enabling continuous production runs, reducing material waste, and improving product consistency. Optimized TIBA usage typically delivers 15-30% productivity gains in polymerization and olefin production processes.

Optimizing TIBA Usage for Maximum Process Economics

Through our partnerships with customers across various industries, we’ve developed specialized approaches to maximize the economic benefits of TIBA in manufacturing processes. Precise dosing strategies represent one of the most impactful optimization opportunities. Many facilities initially use excess TIBA as a conservative approach to ensure adequate scavenging and activation. However, our experience shows that carefully calibrated reduction in TIBA concentration often maintains full performance while significantly reducing costs.

Continuous flow chemistry approaches have revolutionized TIBA utilization efficiency in many applications. By implementing continuous dosing systems rather than batch addition, we’ve achieved more consistent catalyst performance while reducing the total quantity of TIBA required. These systems typically incorporate real-time monitoring of key process parameters to adjust TIBA addition rates automatically as conditions change.

For polymerization processes specifically, we recommend implementing staged TIBA addition protocols that target different concentrations at various points in the reaction cycle. The initial stage typically requires higher TIBA levels to effectively scavenge system impurities, while later stages can operate with reduced concentrations focused primarily on maintaining catalyst activity. This approach has yielded TIBA consumption reductions of 15-25% without compromising product quality.

Recovery and recycling strategies offer another avenue for improving TIBA economics. In some continuous processes, unreacted TIBA can be recovered from process streams and reused after appropriate purification. While this requires additional equipment investment, the payback period is often surprisingly short for operations with high TIBA consumption volumes.

Integration of TIBA management into broader process control systems enables more sophisticated optimization. By correlating TIBA usage with product quality parameters, production rates, and other operational variables, we can develop predictive models that suggest optimal TIBA strategies for different production scenarios. This data-driven approach can be developed through collaborative process analysis.

Beyond direct process improvements, optimized TIBA usage delivers several secondary benefits that contribute to overall manufacturing efficiency:

- Reduced catalyst waste and associated disposal costs

- Lower cleaning requirements between production runs

- Fewer off-specification products requiring rework or downgrading

- Improved production scheduling flexibility due to more consistent process performance

- Reduced safety incident risk through minimized material handling

Conclusion

Triisobutylaluminum (CAS 100-99-2) remains essential in modern chemical manufacturing, enhancing polymerization processes, olefin production, and manufacturing efficiency while requiring specialized safety protocols and reliable supplier partnerships for optimal results.

[^1]: Explore the diverse industrial applications of Triisobutylaluminum to understand its significance in enhancing production efficiency and product quality.

[^2]: Learn about innovative strategies to enhance catalyst efficiency, which is crucial for optimizing production yields and maintaining product quality.

[^3]: Discover the latest advancements in polymerization processes to stay updated on techniques that improve efficiency and product characteristics.

[^4]: Learn about Linear alpha olefins, their significance in various industries, and how they are produced using Triisobutylaluminum.

[^5]: Discover comprehensive safety protocols for handling Triisobutylaluminum to ensure safe operations and compliance in chemical manufacturing.