- Tel: +86-531-88897198

- [email protected]

Advanced Organoaluminum Reagent for Polyolefin Catalysis & Precision Synthesis

|

Parameter

|

Specification

|

|---|---|

|

Chemical Name |

Diisobutylaluminum Hydride |

|

CAS Number |

1191-15-7 |

|

Molecular Formula |

C₈H₁₈AlH |

|

Molecular Weight |

142.22 g/mol |

|

Purity |

≥98.0% |

|

Appearance |

Colorless to slightly yellow transparent liquid |

PRECISE REDUCTION AGENT

HIGH PURITY, HIGH SELECTIVITY

RELIABLE GLOBAL SUPPLY

TUODA’s Diisobutylaluminum Hydride (DIBAL-H) is a premium-grade reducing agent used in selective reductions and functional group transformations across pharmaceutical and fine chemical manufacturing. With ≥98% purity and precise reactivity, it is essential for producing high-value intermediates with excellent selectivity and yield.

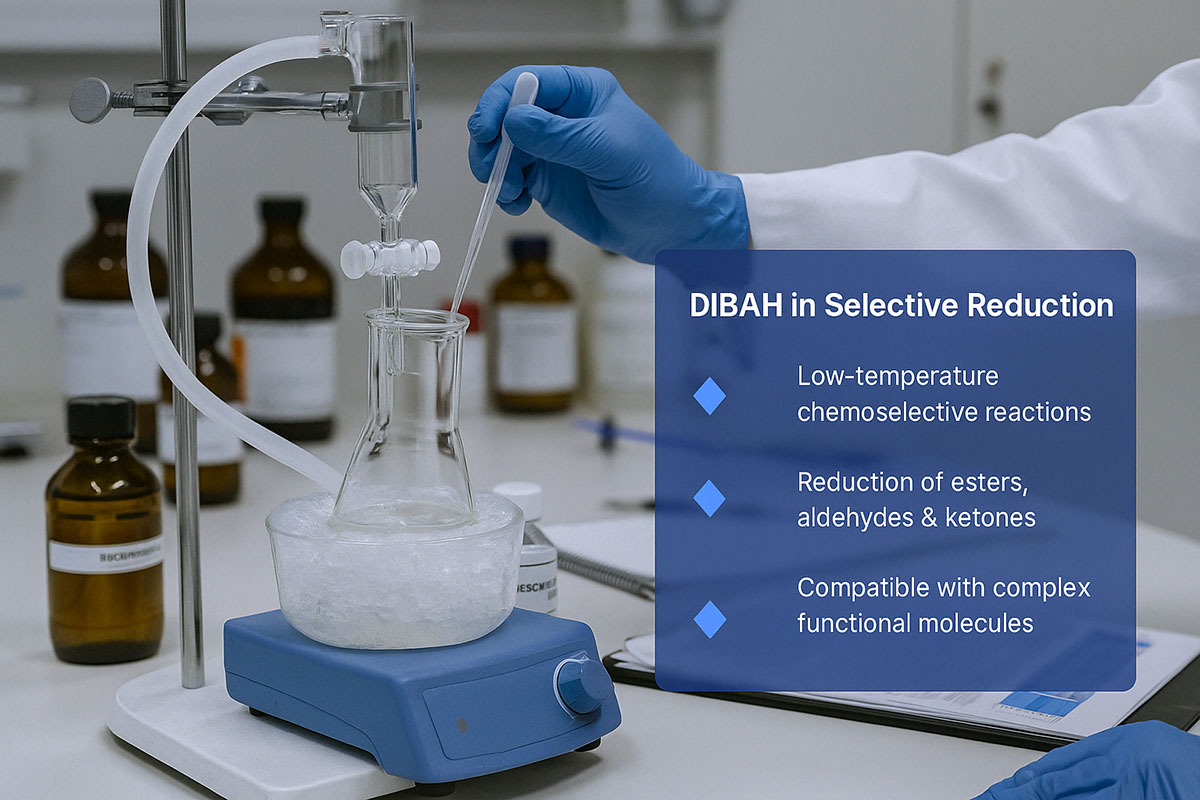

Diisobutylaluminum Hydride (DIBAL-H), CAS 1191-15-7, is a highly selective organoaluminum reagent, widely applied in fine organic synthesis. It enables mild, chemoselective reductions—particularly for converting esters to aldehydes, and for selective deoxygenation steps in complex molecule development.

Backed by over a decade of expertise, TUODA ensures strict batch-to-batch consistency and high-purity output, minimizing byproducts in sensitive processes.

Manufactured in GMP-compliant facilities and packed under inert gas, TUODA’s DIBAL-H offers long-term stability, safe handling, and reliable performance even under demanding synthesis conditions.

Industry-Leading Quality Parameters for Diisobutylaluminum Hydride (DIBAL-H)

All specifications are verified through strict quality control protocols. Customized packaging and documentation available upon request.

Why TUODA’s Diisobutylaluminum Hydride (DIBAL-H) Sets the Industry Standard

Industry-leading purity exceeding 98.0%, ensuring clean reduction reactions, fewer byproducts, and higher selectivity in fine chemical and pharmaceutical synthesis.

Stabilized under inert atmosphere with advanced packaging and production safeguards to extend shelf life and preserve reducing activity.

Optimized hydride reactivity tailored for selective reductions, enabling efficient conversion of esters, nitriles, and amides with excellent chemoselectivity.

Supported by decades of experience in organoaluminum chemistry, our technical team helps you unlock the full potential of DIBAL-H in your synthesis workflow.

Experience the difference that ultra-pure DIBAL-H can make in your selective reduction processes

Diisobutylaluminum Hydride's Versatile Role in Modern Industrial Processes

Primary application as a chain termination agent in olefin polymerization, providing precise molecular weight control and polymer end-group functionality.

Used in selective reduction of esters, aldehydes, and ketones to alcohols, with exceptional chemoselectivity for complex molecule synthesis.

Facilitates stereoselective transformations of complex pharmaceutical intermediates and enables challenging reductions with high stereoselectivity.

Acts as a powerful and selective reducing agent in the synthesis of specialty chemicals, fragrances, and advanced materials.

Utilized in modification of heterogeneous catalysts and as a reducing agent in the production of specialized petrochemical intermediates.

Essential reagent in academic and industrial research for developing novel reduction methodologies and asymmetric synthesis protocols.

Diisobutylaluminum Hydride (CAS:1191-15-7) plays a crucial role in modern polymer manufacturing processes, particularly in controlling molecular weight and introducing specific end-group functionality.

Our high-purity DIBAH ensures consistent performance in polymer production, resulting in materials with precise specifications and enhanced end-use properties.

A leading specialty polymer manufacturer implemented TUODA's DIBAH and achieved a 20% improvement in molecular weight control and 35% reduction in polydispersity index, significantly enhancing product performance.

Diisobutylaluminum Hydride(CAS:1191-15-7) is a powerful and highly selective reducing agent capable of transforming various carbonyl compounds to alcohols with exceptional chemoselectivity.

Our ultra-high purity DIBAH delivers consistent reactivity and selectivity, critical for complex transformations in fine chemical and pharmaceutical synthesis.

A pharmaceutical research team utilized our DIBAH in the total synthesis of a complex natural product, achieving 98% selectivity in a critical reduction step that preserved four other sensitive functional groups.

Diisobutylaluminum Hydride(CAS:1191-15-7) serves as a critical reagent in pharmaceutical synthesis, enabling complex transformations and stereoselective reductions essential for API manufacturing.

Our pharmaceutical-grade DIBAH is produced under strict quality control, ensuring batch-to-batch consistency critical for validated pharmaceutical processes.

A major pharmaceutical company implemented our DIBAH in their manufacturing process for an antiviral drug intermediate, achieving 99.5% stereoselectivity and reducing production costs by 25%.

Diisobutylaluminum Hydride(CAS:1191-15-7) is extensively used in fine chemical synthesis as a versatile reducing agent for various transformations requiring high selectivity and mild conditions.

Our DIBAH provides consistent reactivity and high selectivity, critical factors in the production of high-value fine chemicals with precise specifications.

A leading fragrance manufacturer implemented our DIBAH in their synthesis of a key aroma compound, achieving 99.8% purity and reducing production cycle time by 40%.

Diisobutylaluminum Hydride(DIBAL-H) plays important roles in catalyst preparation and modification, particularly in heterogeneous catalysis systems used in petrochemical processes.

Our industrial-grade DIBAH delivers reliable performance in catalyst preparation, with the stability and reactivity required for consistent catalyst properties.

A specialty catalyst manufacturer utilized our DIBAH in their platinum catalyst preparation process, achieving 45% higher activity and 30% improved selectivity in their hydrogenation reactions.

Diisobutylaluminum Hydride(DIBAL-H) is an essential reagent in academic and industrial research laboratories, enabling the exploration of new reduction methodologies and asymmetric synthesis protocols.

We offer research-grade DIBAH in various package sizes suitable for laboratory use, with comprehensive safety documentation and technical support.

A university research group utilized our high-purity DIBAH to develop a novel asymmetric reduction protocol for β-keto esters, achieving up to 98% enantiomeric excess and establishing a new methodology for chiral alcohol synthesis.

Discover how our high-purity Diisobutylaluminum Hydride can enhance your specific application

Industry-Leading Diisobutylaluminum Hydride with Exceptional Reductive Performance and Selectivity

| Chemical Formula: | AlH(C₄H₉)₂ |

| Molecular Weight: | 142.24 g/mol |

| CAS Number: | 1191-15-7 |

|

Parameter

|

Standard Grade

|

High-Purity Grade

|

Ultra-Pure Grade

|

|---|---|---|---|

|

DIBAL-H Content |

≥ 95.0% |

≥ 98.0% |

≥ 99.5% |

|

Aluminum Content |

≥ 20.0% |

≥ 21.5% |

≥ 22.0% |

|

Hydride Content |

≥ 90.0% |

≥ 95.0% |

≥ 99.0% |

|

Free Al |

≤ 0.3% |

≤ 0.1% |

≤ 0.05% |

|

Iron |

≤ 20 ppm |

≤ 10 ppm |

≤ 1 ppm |

|

Heavy Metals (total) |

≤ 50 ppm |

≤ 20 ppm |

≤ 5 ppm |

|

Property

|

Value

|

|---|---|

|

Appearance |

Clear to light yellow liquid |

|

Density |

0.854 g/cm³ at 25℃ |

|

Melting Point |

-98.0℃ |

|

Boiling Point |

142℃ at 760 mmHg |

|

Vapor Pressure |

0.18 kPa at 20℃ |

|

Flash Point |

11℃ (closed cup) |

|

Solubility |

Reacts violently with water; soluble in hexane, heptane, toluene, and aliphatic hydrocarbons |

Extremely pyrophoric—ignites spontaneously upon exposure to air. Must be handled under strict inert gas protection (nitrogen or argon atmosphere) with certified safety measures.

Reacts violently with water and humid air, releasing hydrogen gas and forming aluminum hydroxide. Strict moisture exclusion is required during storage and usage.

Compatible with hydrocarbon solvents and stainless steel. Avoid contact with alcohols, esters, ketones, acids, oxidizers, and halogenated compounds.

Stable at –10°C to +25°C. Begins to decompose above 130°C, releasing flammable gases. Use temperature-controlled storage for safe long-term handling.

Our technical team is available to provide detailed specifications, safety information, and handling guidelines for our Triethylaluminum products.

Rigorous Testing and Strict Quality Management for Consistent Excellence

Each batch of incoming raw materials undergoes rigorous testing to verify purity and compliance with specifications before entering production.

Continuous monitoring throughout the production process with real-time analytics to ensure consistency and detect any deviations immediately.

Comprehensive analysis of each production batch against all specified parameters using advanced analytical techniques.

Application-specific testing to verify product performance in simulated customer processes, ensuring it meets real-world requirements.

Comprehensive documentation package including Certificate of Analysis, traceability records, and quality assurance documentation.

Our quality management system is certified to ISO 9001:2015, ensuring consistent processes and continuous improvement.

Environmental management certification demonstrating our commitment to sustainable manufacturing practices.

Occupational Health and Safety Management System certification for safe handling of hazardous materials.

Compliant with European Union's Registration, Evaluation, Authorization and Restriction of Chemicals regulation.

Our dedicated quality control laboratory is equipped with advanced analytical instruments to ensure the highest standards of product quality and consistency:

For precise determination of DIBAL-H purity and impurity profiles

To detect trace metal impurities down to ppb levels

For moisture content analysis with high sensitivity

For structural verification and identification of functional groups

To confirm structural integrity and batch consistency for organoaluminum reagents.

We partner with our customers to ensure our products meet their specific quality requirements through our comprehensive quality assurance program:

We develop custom specifications to match your unique process requirements.

Tailored quality standards are provided based on your end-use application.

We offer formulation flexibility to meet specialized technical demands.

Each product is adjusted to ensure compatibility with your production line.

Regulatory and safety parameters are aligned with your regional compliance.

Regulatory and safety parameters are aligned with your regional compliance.

Still have questions? Here are answers to the most common queries buyers ask when sourcing high-purity DIBAL-H.

We typically offer a low MOQ starting from 100g to support both lab-scale and bulk requirements.

Yes, we provide samples (100g–500g) for evaluation before committing to larger purchases.

Absolutely. We offer concentration adjustments and customized sealed packaging to meet your technical needs.

Yes, DIBAL-H is pyrophoric and classified as UN2929, Class 4.2. We use UN-approved packaging and provide all regulatory documents.

All batches come with COA, SDS, and detailed analysis. We support ISO 9001 systems and documentation for REACH, RoHS, and other compliance needs.

Store under inert gas (nitrogen/argon) in a dry, cool place below 30°C. Keep away from moisture and ignition sources.

We maintain inventory and can ship within 3–7 days globally via air freight with DG packaging.

Yes, our team offers full documentation support (SDS, TDS, CoA) and application-specific guidance for safe handling and use.

Our DIBAL-H features ultra-high purity (≥99%), stable supply, customizable concentration, and a strong safety guarantee in packaging and transport.

Can’t find your question here? Our team is ready to assist you 1-on-1.

Explore related catalysts and fine chemical intermediates available from TUODA.

CAS:96-10-6

CAS:563-43-9

CAS:12075-68-2

CAS:1191-15-7

CAS:100-99-2

CAS:35794-11-7

Contact us today to receive a free quote and expert consultation on chemical intermediates and petrochemical solutions. Tuoda is ready to provide the perfect solution for your project.

At Tuoda, we transform complexity into simplicity! Follow these 3 easy steps to get started today:

Share your requirements, and we will give you clear details on the quality, price, payment terms, packaging, and delivery time for our chemical solutions, helping you plan your procurement. A customized quote will be provided within 24 hours.

Once you approve the details and provide the deposit, we’ll begin mass production and handle all the logistics to ensure smooth delivery.

Our commitment is to deliver high-quality, reliable chemical products on time, helping you meet your production goals.

WhatsApp us

Have a question or need a quote? Fill out the form below, and our team will get back to you as soon as possible!

TUODA Chemical Support

Technical Support

TUODA Chemical Support

Hello, this is TUODA. How can we assist you today?